Electronic components generally use oxide ceramics, and magnesium oxide has a large surface activity and high temperature characteristics, so it is the main raw material in oxide ceramics. In the research and development of high-purity and high-density electronic component materials, high-purity magnesium oxide uses magnesium oxide with a purity of more than 99.5% as raw material due to its own characteristics, which can ensure the purity of electronic components.

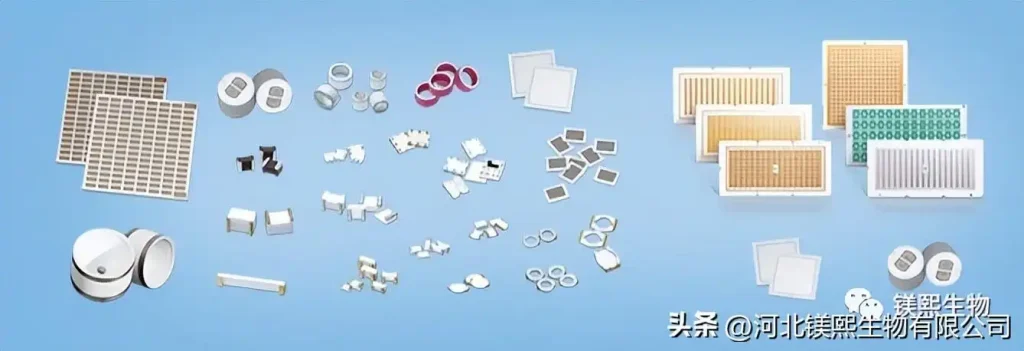

The high-purity nano-magnesium oxide independently developed and produced by Hebei Messi Biology Co., Ltd. is widely used in high-temperature heat-resistant materials, ceramic materials, electronic substrates and other materials. High-purity nano-magnesium oxide is produced by advanced technology, with a purity of more than 99.95% and an average particle size of 10nm. Compared with traditional technology, it has the advantages of high product purity, fine particle size, large specific surface area, and good dispersion. It has excellent alkali resistance and electrical insulation at high temperature, high thermal expansion coefficient and thermal conductivity, and good light transmission. Also has good sintering properties. Low-temperature sintering can be achieved without the use of sintering aids, and high-density fine-grained ceramics or multifunctional magnesium oxide films can be produced, which are expected to be developed as electronic component materials under harsh conditions such as high temperature and high corrosion.

Hebei Messi Biology Co., Ltd. stated that the demand for magnesium oxide for electronic ceramics is mainly concentrated in piezoelectric ceramics. The purity of magnesium oxide is required to be above 99.5%. It is used to prepare ceramic capacitor dielectric materials with low dielectric loss and good material uniformity. , suitable for the production of multilayer ceramic capacitors with large capacity, high insulation resistivity, ultra-thin dielectric layer (dielectric layer thickness less than 10μm), and its addition amount is 0.5-5%. Magnesium oxide for electronic ceramics has special requirements, such as particle size distribution, crystal structure, fineness, activity, heavy metals, whiteness, iron, wear resistance, high temperature resistance, etc., which can be customized according to specific special requirements.

https://tibetmag.com/the-role-of-magnesium-oxide-in-electronic-ceramics/

0 Comments