Magnesium hydroxide (magnesium hydroxide,) as an important chemical product and intermediate, has a wide range of applications. In the field of environmental protection, it is called “green and safe water treatment agent”, which can be used for neutralization of acid-containing wastewater, decolorization of printing and dyeing wastewater, removal of heavy metals, flue gas desulfurization, etc. It can also be used as antacid agent for medicine, antibacterial and bactericide, protective agent for paper and precursor for preparing magnesium oxide.

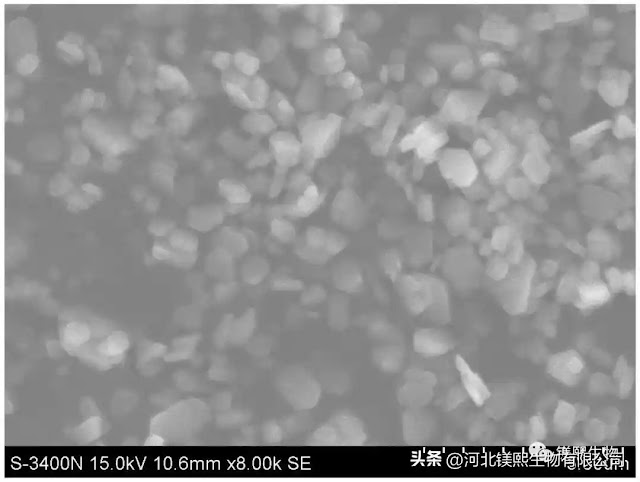

As an environmentally friendly inorganic flame retardant, magnesium hydroxide has the advantages of environmental protection, high thermal stability, flame retardancy, smoke elimination, and drip resistance, and has become a research hotspot for scholars. However, the magnesium hydroxide synthesized under normal temperature conditions is mostly agglomerated solid, the average particle size of a single particle is small, the specific surface area (BET) is large, the surface polarity and microscopic strain of the (101) surface and (110) surface are large, and the crystal grains are easily Secondary agglomeration occurs, and the dispersion in high molecular polymer materials is poor, which affects the processing performance of composite materials.

Hebei Messi Biology Co., Ltd. stated that hydrothermal modification technology is an effective method to reduce the surface polarity and surface microscopic strain of magnesium hydroxide, increase crystal crystallinity, and improve particle dispersion. However, direct hydrothermal magnesium hydroxide slurry, due to the high hydration characteristics of magnesium hydroxide, there is a large amount of crystal water on the surface of the new nucleus, which hinders the superposition of growth elements on the surface of the new nucleus and inhibits crystal growth. It takes a long time and consumes a lot of energy. The researchers also explored…

0 Comments